Lime Slurry Injection System Tips

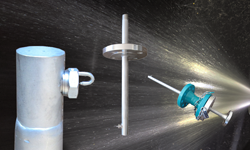

Use a removable corporation style injector.

A 316L S.S. solution tube is best.

Dissolved solids tend to precipitate out of the process water where lime slurry or other alkaline substance is applied.This can cause plugging of the line over time.

For applications that are difficult to take out of service for maintenance, consider having a duty/standby injector arrangement.

Drops in line pressure increases in the piping can cause a reduction in the saturation point of slurry solution and result in scaling of the piping.Ensure piping is very smooth and designed without fittings that will cause a significant pressure drop.

Be aware of temperature of the piping throughout the system.Warmer temperatures can cause a saturated lime solution to become supersaturated and cause the solution to precipitate and form scaling.

If possible have backup injectors and piping systems.

Consider alternating the chlorine solution with the lime slurry solution on a regular basis to eliminate scaling.

Keep line lengths to a minimum.

Eliminate any points of low velocity in the slurry lines.

Slope lines to prevent any low spots that can trap particlesKeep the velocity in the feed lines between 4-7 ft/sec.

Piping should not be oversized to accommodate estimated future system capacity.

Whenever lime slurry feeding is stopped for any reason, the line should be flushed with clear water.

In smaller plants a flexible PVC hose is used for the entire feed line so that stoppages can be eliminated by shaking or bending the feed line.

Design system for easy cleanout, removal or flushing.Consider using Tees and crosses as elbows to facilitate cleaning.If this is not possible, use a sweep elbow (5 x diameter) to eliminate sharp bends.

On larger systems use a recirculating pump to constantly circulate the slurry to the point of injection and back to the storage tank.If the feed requirement is “X”, then pump approximately 3X to the feed point and return 2X back to the tank.

If there are branch circuits (such as drains or lines to day tanks) the lines should be on the top of the pipe to prevent settling of particles behind the closed valve.

All valves should be pinch valves or self-cleaning ball valves. Use a throttling valve on the return piping to prevent sudden pressure drops (and precipitation.A pinch valve is best.

Use Polyphosphates in dilution water to inhibit scaling.

Use softened water to reduce the minerals that can cause scaling.

Allow the Lime slurry adequate time to achieve a stable suspension.

Use a slurry concentration not exceeding 1 lb/gal (120 g/L).

Ensure that slurry storage tank is properly agitated to ensure that the lime, impurities and precipitated salts remain in suspension (typically 0.5-1 hp (370-746 W) per 1,000 gal with a slurry concentration of less than 1 lb/ gal (120g/L)

Material Recommendations

Gaskets and O-rings

Buna-N, EPDM, Viton

Metals

Stainless Steel

Plastics

PVC, Kynar, Teflon

Background-Lime Slurry Uses

Lime is used for softening, agglomeration, flocculation, and the pH adjustment of the drinking water. For the distribution system, lime is often added to control carbonate deposition and prolong its useful life.For waste water the coagulant action of lime neutralizes the negative charge on colloid particles contained in water. It also causes the flocculation of suspended impurities which makes decanting easier. Lime acts as the flocculating agent to which metallic salts and/or polymers can also be added. The use of lime to increase pH levels can precipitate most heavy metals in the form of hydroxides. When waste waters contains phosphates and sulfates, lime makes it easier to precipitate them as well as the heavy metals, in the form of insoluble salts - Ca3(PO4)2, CaSO4 - that are easier to collect.

Chemical Forms

Lime slurries are commonly expressed as pounds/gal of water of CaO of CaOH2, although this can be confusingif the dry weight (oxide or hydroxide) is not specified.

Lime suspensions fall into three categories:

-

A wet putty-likematerial containing 30-35% quicklime Slurry

-

A creamy material that can be poured or pumpedwith about 20-25% quicklime Milk of Lime

-

A watery consistency that is milky in colorand is less than about 18% in (typically 10-15% or 1-1.5 lb/gal) concentration.This is often produced as the final product from past or slurry after a secondary dilution and is easiest to inject.

Lime slurry is a stable suspension and is not corrosive once the slurry has been stabilized by allowing all of the water to fully react with the calcium hydroxide (usually about 15 minutes minimum).The dissolved solids from the dilution water will precipitate if injected before stabilization, on piping and injectors and form scale.