Concentrated Acid Solutions

|

|

|

|

|

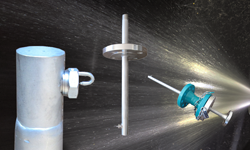

| Flanged Diffusers | Threaded Injectors | Tank or Vessel Spargers | Mixing Tees |

Our page on Concentrated Sulfuric Acid has useful information for planning an acid injection system.

Some recommendations include:

- Do not oversize the injection quill diameter. You will want a high enough flow rate inside the quill that the process flow cannot backflow inside the quill diameter and react. This will reduce heating and damage/corrosion by high spot temperatures due to the heat of reaction.

- Keep the acid piping as small as practical. This will reduce the volume of acid available to react with the process liquid. If possible run small diameter tubing or piping to the injector.

- Consider using multiple check valves. The check valve seal between the process fluid and concentrated acid can become hot (spot temperatures up to 350 degF under the wrong conditions) as the check valve corrodes or leaks. Multiple check valves will reduce the inevitable degradation of the check valve by reducing the ability of the acid in the line to reach the check valve seal.