Aqua Ammonia Injection System Tips

When injecting the small amounts of ammonia that are typically added to a water supply, be aware that it is difficult to quickly disperse chemicals when the additive amount is a small amount (typically measured in gallons per hour).

Small additive chemical flowrates will noticeably have greater variation in their dispersion merely due to the physics of mixing.

The best way to dilute small amounts of chemicals is through the use of liberal amounts of softened carry water. This will quickly provide the level of chemical diffusion and mixing desired, and allow for a simpler injector arrangement.

Additionally, a good dilution program will less the effects of disinfection by-products (DBP’s), as diluted chemicals are less likely to produce unexpected organic substances.

When chloraminating, add the ammonia to the water first and then add the chlorine. This will generally prevent the formation of compounds that produce chlorinous taste and odors.

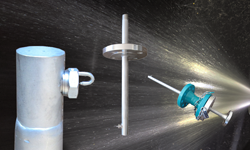

The injectors are typically a corporation stop style injector or a thin-wall diffuser (a multi orifice design to disperse the chemicals or the use of multiple bayonet style injectors). As aqua ammonia is a scaling chemical, the injectors may need to be removed on occasion to clean any hardness deposits that occur on the injector. For pipelines that cannot shut down, it is recommended that a corporation style injector that be installed. Soft water dilution of the aqua ammonia will also reduce scaling of the injectors.

General Materials of Construction

Metals

Stainless Steel is recommended for most injector applications. Other metals that are compatible include Hastelloy alloys, carbon steel, aluminum and cast iron.

Do not use copper, brass, silver brazing, nickel, or Monel.

Plastics

Most plastics including PVC, PVDF (Kynar), Teflon, & polyethylene are suitable for aqua ammonia contact.

Elastomers

Neoprene, Ethylene Propylene, Buna, Butyl, Teflon are all acceptable for aqua ammonia use.

Do not use Natural Rubber, nitrile, polyurethane, Hypalon, Silicon, or Viton

Background

Aqua ammonia, aqueous ammonia and ammonium hydroxide are synonymous terms referring to a solution of ammonia in water. The chemical formula for ammonium hydroxide is NH4OH. Hydrated molecules of NH3 may halso exist as NH3 ●H2O or NH3●2 H2O.

Ammonia dissolved in water is commonly referred to as simply “ammonia”. This usage of the word does not refer to anhydrous ammonia.

Aqua ammonia is classified as a weak base. Typically the pH of an ammonia solution will be between 11 and 12, compared with a pH of about 14 for sodium hydroxide solutions.

The most common aqua ammonia concentration is 29.4% ammonia by weight (also known as 26 Bé [degrees baume].

Baumé is related to specific gravity by the formula:

º Bé = (140/specific gravity)-130

“26 º Baumé density at 60 º F”, “29.4% ammonia by weight” and “0.8974 specific gravity at 60 º F” are all terms referencing an identical concentration of aqua ammonia.

Dilution Calculations for Aqua Ammonia

Calculating the amount of ammonia or water to make a specific concentration of aqua ammonia does not follow normal dilution rules.

The anhydrous ammonia and aqua ammonia volumes are not additive with water volumes, i.e. one gallon of anhydrous ammonia added to nine gallons of water does not result in 10 gallons of solution. The final volume would be less than 10 gallons. For many aqua dilutions, the non-additive effects are minimal. For anhydrous additions, they are significant.

The steps to calculate dilutions correctly are as follows:

Let:

Vo = volume in gallons of original concentration aqua ammonia or anhydrous ammonia

Co= concentration in wt. % NH3 of anhydrous ammonia or original aqua ammonia solution used.

Vf = volume in gallons of final solution desired

Cf = concentration in wt.% NH3 of final aqua ammonia solution desired

Vw = volume in gallons of water to be added

Determine specific gravities at 60ºF/60ºF of both original and final concentrations of aqua ammonias by referring to “Specific Gravity of Aqua Ammonia” table. Use interpolation to calculate intermediate values.

![]() Download "Specific Gravity of Aqua Ammonia" Table (54 kb) (also includes heat of dilution information)

Download "Specific Gravity of Aqua Ammonia" Table (54 kb) (also includes heat of dilution information)

For anhydrous ammonia, use a specific gravity of 0.6182

Let SGo= specific gravity of anhydrous ammonia or original concentration of aqua ammonia

SGf = specific gravity of final concentration aqua ammonia

SGw = 1.0000 specific gravity of water.

Two laws are clear:

First, the weight of the original anhydrous ammonia or aqua solution plus the weight of the water added must equal the weight of the final solution.

Second, the weight of the ammonia (NH3) present originally (either as anhydrous ammonia or in the original aqua ammonia) must equal the weight of the ammonia (NH3) in the final solution.

Therefore, two equations with two unknowns are generated from which desired values can be calculated.

The “ammonia equation” becomes:

(Vo)( SGo) (Co) = (Vf)( SGf)( Cf)

and the “weight equation”

(Vo) (SGo) + Vw = (Vf)( SGf)

Example: what volume of anhydrous ammonia (would you add to what volume of water to obtain 1,000 gallons of 29.4% aqua ammonia?

The “ammonia equation” becomes:

Vo = Vf (SGf)( Cf)/( SGo)( Co)

Or Vo = 1,000 (0.8974)(0.294/(0.6182)(1.00)

Or Vo = 426.7 gallons

The “weight equation” becomes:

Vw = (Vf)( SGf) – (Vo)( SGo)

Or

Vw = (1,000)(0.8974) – (426.7)(0.6182)

Or

Vw = 633.6 gallons

Note that 426.7 = 633.6 does not equal 1,000.

There has been a decrease of about 6% in volume in the mixing process.

![]() Download "Dilution Calculations for Aqua Ammonia" (56 kb)

Download "Dilution Calculations for Aqua Ammonia" (56 kb)

Storage

Concentrated aqua ammonia will quickly lose strength during storage, particularly in warm weather. To prevent loss of the ammonia, several different arrangements can be used:

- Gaseous ammonia be injected upstream of the injector using an ammoniator. A venturi eductor or static mixer can be installed at this point, but the high affinity of ammonia for water typically will not require any type of mixing technology for low concentrations of ammonia

- A chemical chiller can be used to keep the aqua ammonia water to a temperature below 60 deg F. This will greatly reduce the loss of ammonia in a tank that is open to atmospheric pressure by reducing the partial pressure of the aqua ammonia. The advantage of dosing room pressure ammonia is that it is easier to regulate the dosing flow rate when the chemical additive is at room pressure. Inyo Process can provide chemical chillers that will allow for easy storage of aqua ammonia solutions.

- A pressurized tank can be used to hold the aqua ammonia. As the maximum pressure that the tank will see is low, there are some alternative poly tanks that can withstand the pressures that aqua ammonia will produce under normal conditions. The standard methodology is to use an ASME code pressure vessel (Max allowable working pressure of 25 psig). If you are using a pressurized tank, the tank should be equipped with a relief valve in accordance with the design pressure. Each tank should also be equipped with a vacuum breaker set at 2-4 ounces of vacuum. The discharge from relief valves shall be directed unobstructed to the air and away from personnel.