Polymer Injection into Sludge for Dewatering

Inyo Process has a range of solutions for dispersion of dilute polymer into a sludge or slurry including:

- Sludge Injection Disk

-

Sludge Injection Spools for Mining Tailings (at bottom of page)

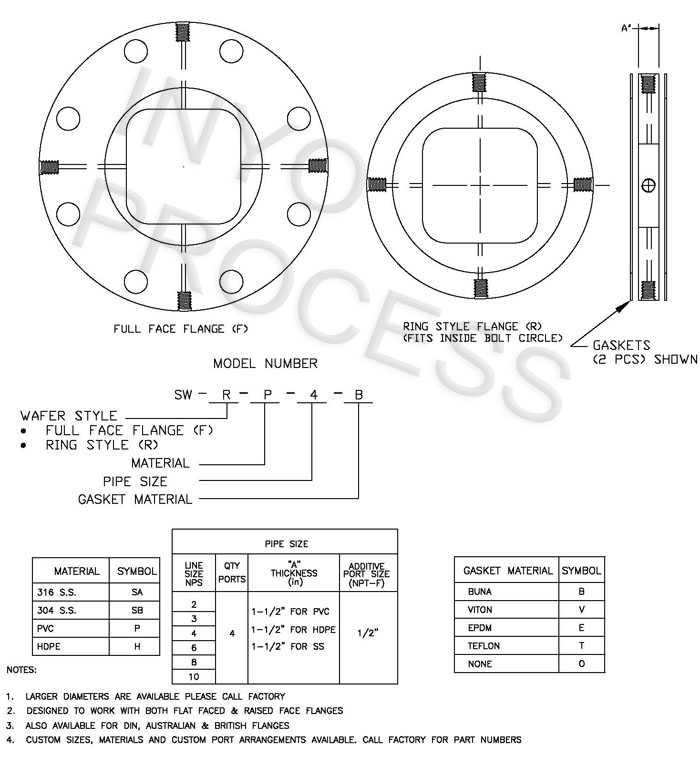

Sludge Injection Disk

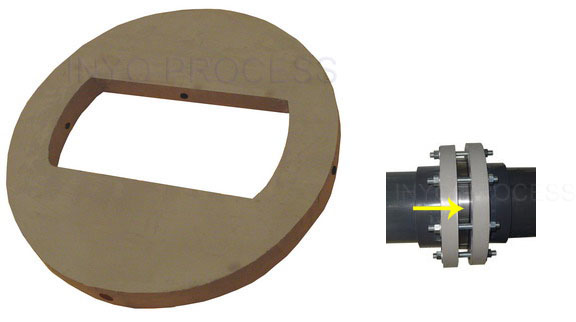

(Shown) Sludge Wafer Disk sandwiched between flanges (injection port not shown)

Designed to specifically for mixing polymer to sludge applications before dewatering, this wafer injector distributes polymer evenly throughout the sludge. Sludge Wafer is designed to fit between 125# or 150# flanges.

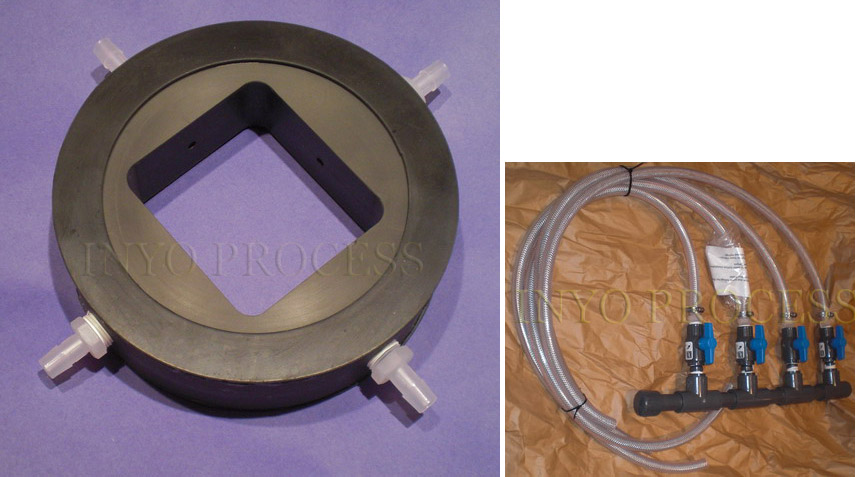

Typical sludge wafer disk (10" dia.disk shown) designed to provide even distribution of polymer. Shown with optional manifold assembly

Advantages

Provides excellent mixing for sludge/ polymer mixing. Polymer is injected deeper into the sludge stream for better mixing.

Non-plugging, single opening design with no place for fibers or small debris to hang up in wafer.

Able to pass debris up to 3/4 the size of the pipe diameter.

Multiple Injectors-The 4 injector ports are position to inject polymer evenly throughout the sludge.

No Fouling--No place for sludge to hang-up as it pass this injection wafer.

Easy installation-Sludge Injector Wafer is sandwiched between flanges.

Easy inspection-Simple to remove the wafer by removing the bolted connection

Ease of Use-Fits into an existing piping without welding.

We can provide wafer injectors that will fit in all domestic and foreign flanges including:ANSI/ASME B16.5 125# & 150# flanges, AWWA C-207, DIN, British Standard, and Australian Standard.

If you need a special version –Contact Us!

![]() Click here to download datasheet (35 kb)

Click here to download datasheet (35 kb)

Inyo can provide alternate styles of injection wafers designed for polymer injection into sludge. Integrated tapered injectors allow for even dispersion of polymer and enhance turbulence in sludge to ensure full distribution of polymer through the (4) ports. Non-fouling design. Full flange design including bolt holes.

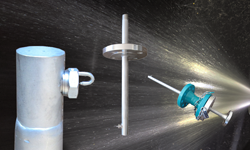

Special slurry injection system with a flanged port for injecting methanol into a slurry stream. The tip of the injector evenly distributes the injected fluid across the the pipe diameter. Non-fouling design.

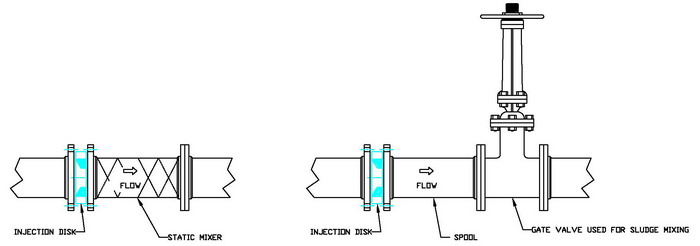

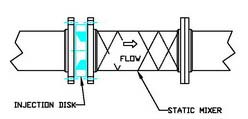

Polymer Injection System for Mature Fine Tailings (MFT)

Oil Sands mining creates many unique problems for polymer injection. The amount of sludge that needs to be treated dwarfs any other sludge/slurry application. When injecting polymer, even minor improvements in the efficiency of the use of the polymer can create large cost savings for the end user by reducing polymer consumption.

The Inyo MFT sludge injection system is designed for the unique challenges of this market.

The Inyo MFT system includes a specially designed non-fouling static mixer suitable for this type of non-newtonian sludge and an injection ring that injects deep into the sludge stream. Contact us for more information.