A West Coast engineering company working on a 60 inch diameter pipeline water project needed to diffuse chlorine and ammonia in the water (chloramination).

In our discussions, the question arose as to how to best diffuse chemicals in such a large pipe.

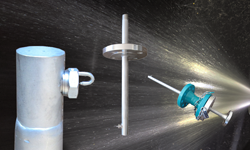

There were several options that we discussed.One is to use a multiple injectors in a radial fashion around the pipeline.Key to proper chemical diffusion is to use an adequate carry water stream to allow the injected jet of chemicals to distribute through the pipe.

Another excellent method of chemical distribution is to use a large diameter sparger that has a multi-orifice design that allows for even distribution of the chemicals by creating a series of plumes.The orifice holes are designed for a high velocity (minimum of 10 ft/sec at the hole, more commonly 15-25 ft/sec).This high velocity has two effects.One is that the chemicals are shot out in a plume into the pipeline for even distribution.

There is a significant back pressure (10-15 psi), which ensures that the chemical distribution is even throughout the pipeline, even for orifice holes that are located at the far end of the sparger.

Both systems have advantages.

The radial multi injector design is simple, and allows for shorter, smaller injectors.For scaling chemicals, the injectors can be corporation stops with removable injection quills, that allow for removal , inspection and cleaning of an individualinjector without shutting down the entire injection system.The down side is that it can be tricky to obtain even distribution of chemicals across all of the injectors (rotameters on each injector may be necessary), and the connection or manifolding of these injectors can be a “birds nest” of tubing or piping connections and valves.Additionally, the injectors will likely need to be fabricated from a Hastelloy C-276 alloy (or a metal encased kynar or Teflon injector) to have adequate cantilever support again the force of the water flow.

The large diameter sparger advantages including a lower cost (The sparger is typically a flanged multi-orifice injector that is supported on both ends of the pipeline), and a much simpler piping arrangement with one or two flanged connections on the pipe.Scaling chemicals such as chlorine or ammonia do not typically present a problem, as the exit velocities of the chemicals is very high and the sparger has very thin wall.Any scale is typically blown off of the orifice hole.As the sparger is a very large diameter and the kynar is very smooth, any scale that forms inside of the sparger will typically fall off to the bottom of the injector.Any scale that forms inside the injector can be cleaned out at service intervals every 1-10 years (The amount of scaling inside an sparger is dependentupon whether the chemical injection ever is stopped and allows for water to infiltrate into the injector to cause scaling).