Atomizers

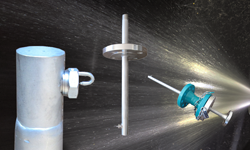

Inyo Process can offer a wide range of atomizers. When you need to add a liquid to a gas stream, we can provide a solution including:

- Corrosion Inhibitors

- Mercaptan addition to natural gas pipelines

- Lubricants

Low flow rate spray nozzles

High flow rate spray nozzles

As part of the atomizer assembly we can also provide the spray nozzles for a completed, integrated solution.

We can also provide retractable atomizers. If you can provide to us your process information, we can offer an optimized solution!

Sampling Probes & Sampling Quills

Inyo offers a wide variety of sampling probes to meet your needs.

Sampling probe arrangements include:

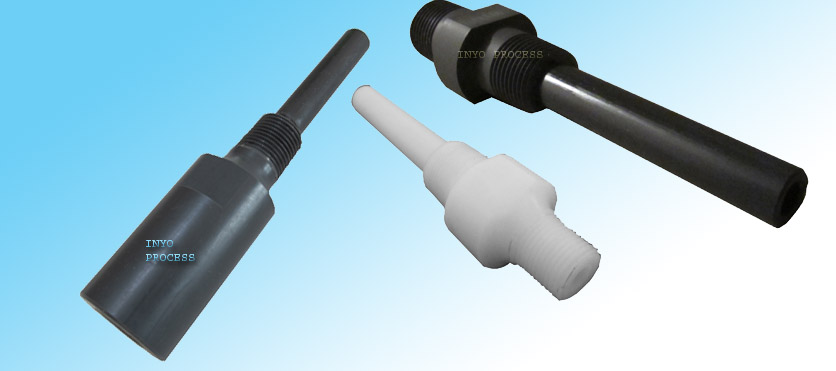

Threaded Style

- Metal quills

- Plastic quills

- Multi-hole diffusers

- Custom threaded quills such as the Aramco AE-036046

Retractable Style

Large Diameter Pipeline Sampling

When sampling a larger pipeline, for a chemical (such as chlorine) which may not be fully distributed, a multi-orifice sampling probe may improve the accuracy of your measurements by averaging the sample taken across the entire pipeline.

These multi-orifice style sampling probes are available in flanged and threaded

version along with removable corporation stop styles.

Inyo can also provide a special version for channel or aqueducts to average measurement and boost accuracy of your injection process—Resulting in saving money on your chemical costs!

If you need a special style sampling probe, contact us.

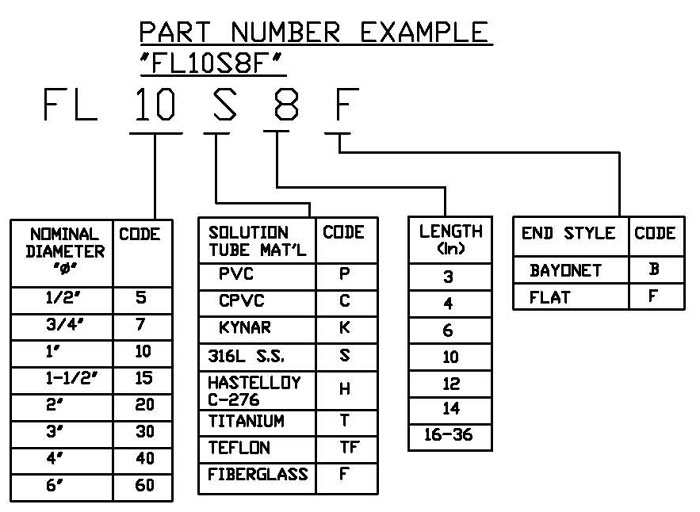

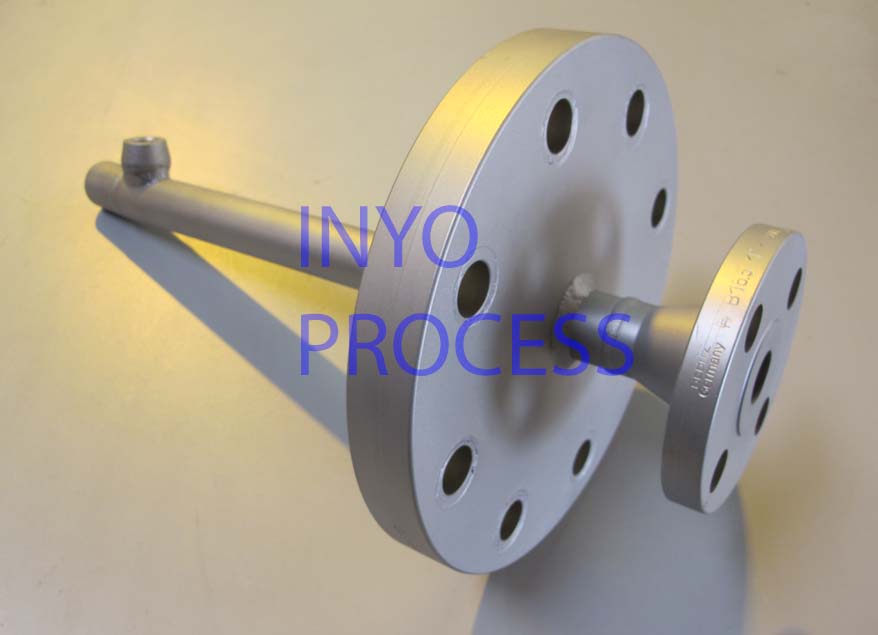

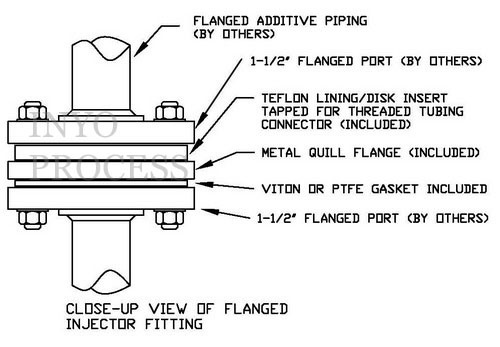

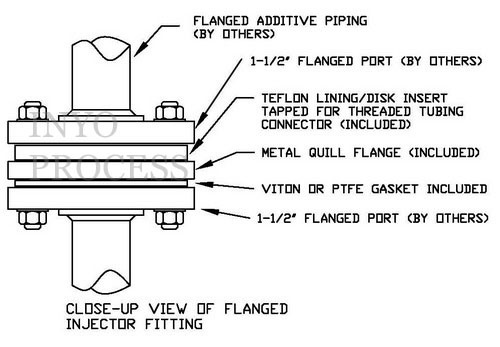

Flanged Injector

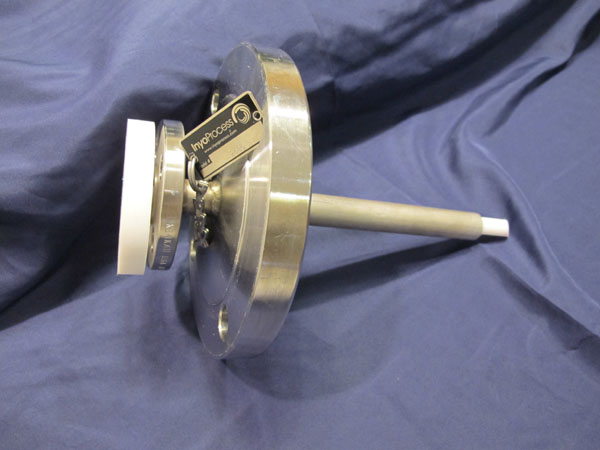

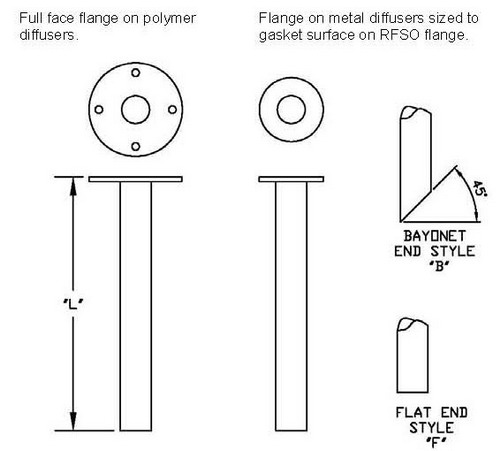

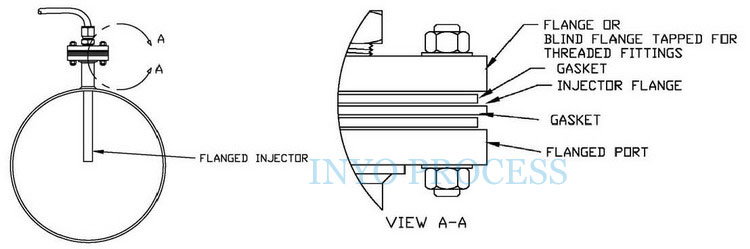

Flanged injectors are designed for single point injection (either through a flat or bayonet style end fitting).

Inyo’s flanged injectors are designed to fit into a flanged additive port. The diffuser flange is sandwiched between the flanged port and a mating blind flange or flanged pipe.

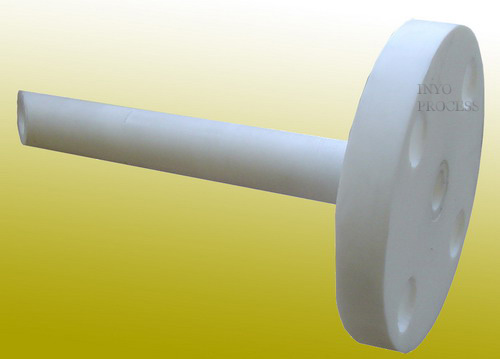

Injectors provide an effective method of chemical diffusion by injecting in the turbulent flow stream toward the center of the pipe. Injectors are offered in a range of chemical compatible materials, and will keep corrosive chemicals away from the pipe walls or additive port fittings. Teflon injectors are an excellent choice for concentrated sulfuric acid injection!Chemical injectors are available in a variety of materials including:

-

Teflon

-

Kynar

-

316L S.S.

-

Hastelloy C-276

-

Titanium

-

PVC

-

CPVC

-

Fiberglass

![]() Download brochure for flanged Injectors

Download brochure for flanged Injectors

![]() Download typical injector installation drawing (30 kb)

Download typical injector installation drawing (30 kb)

![]() Download specification for flanged injector (24 kb)

Download specification for flanged injector (24 kb)

Inyo Process also can offer double flanged injectors. This style of injector with a blind flange is common, however typically are higher cost, as these require additional components and welding, and may require hydrotesting and additional testing of welds.

Double Flange Style Injector Data Sheet (35 kb)

Double Flange Style Injector Data Sheet (35 kb)

Additional information on choosing an injector can be found at Choosing an Injector or Chemical Diffusion System .

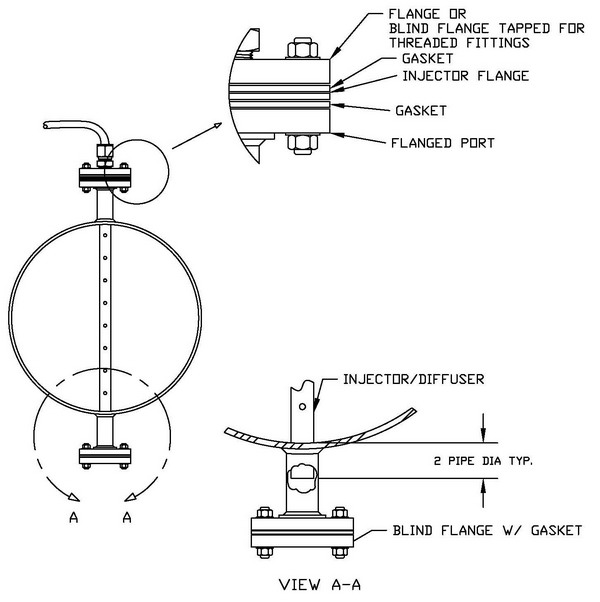

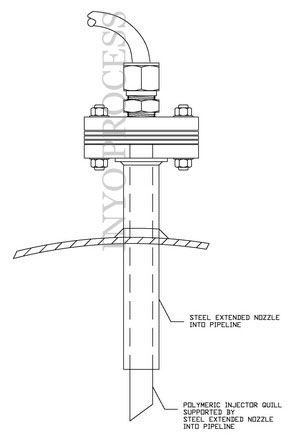

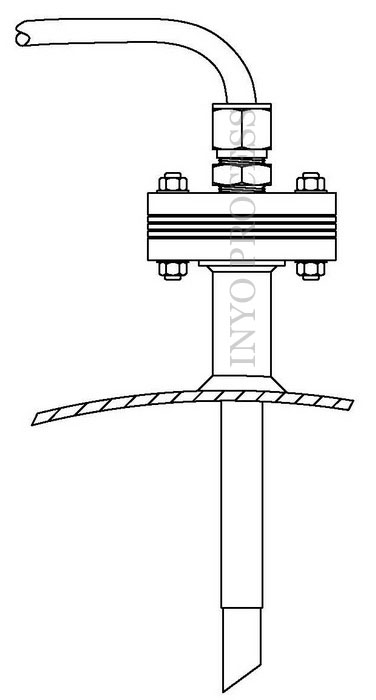

Typical Installation

To support a polymer injector (PVC, Kynar, Teflon) install a longer nozzle in your pipeline that extends within 2-6" of the tip of the polymer injector. You gain the strength of steel, and the chemical resistance of the polymer. Perfect solution for injection chemicals into large diameter pipelines.

RTJ Flanged Injector

Teflon Lined Flanged & NPT Injectors

Perfect for injection of concentrated acids in large diameter pipelines where injectors need strengthening to reach the center of the pipeline and resist the turbulent water forces.

Teflon lined injectors are suited for injecting corrosive liquids such as concentrated 98% sulfuric acid or sodium hypochlorite.The outer support piping (Typically stainless steel) provides the support needed for longer injectors to inject in the turbulent center of the pipeline. The inner teflon lining can handle the heat of dilution of concentrated sulfuric acid Both threaded and flanged end fittings are available to easily connect to your chemical feed system.

Options include:

-

Other polymeric liner materials including Kynar PVDF and PVC/CPVC.

-

Outer support piping available in nearly all materials.

-

Additional sizes are available. Contact Inyo for more details.

-

Available in ANSI 150#, DIN, British and Australian flange systems.

Typical injector installation

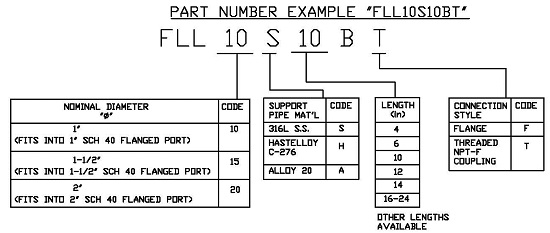

![]() Download Teflon lined injector part number matrix drawing (30 kb)

Download Teflon lined injector part number matrix drawing (30 kb)

Example of Custom Flanged Injection Quills

A PTFE injection quill designed for a 2" 300# flange connection with schedule 160 nozzle piping. Attached to an 18" pipeline designed for a waste water application in a Northeastern U.S. refinery, this injector handles a flow of 2 gph of concentrated sulfuric acid used for pH adjustment. The injector is designed to extended 6" into the pipeline and the large diameter design can withstand the water velocity forces in the pipeline.

These injectors were used for injecting concentrated sulfuric acid into large process water storage tanks. These stainless steel supported PTFE injectors provided a "shower head" arrangement halfway into the tank-Taking a stream of concentrated sulfuric acid and breaking it into a series of smaller streams for better distribution and reaction with the water. The entire assembly fit through a single flange located on the top of the tank. A mechanical tank mixer in the tank provided additional mixing.

This custom engineered flanged tank injector (Hastelloy construction with a PTFE liner and PTFE nozzles was designed to inject sulfuric acid into a higher temperature tank. This design successfully resists the corrosion that occurs with sulfuric acid at higher temperatures.

Shown is a PTFE lined injector for sulfuric acid injection into a low pressure steam/water line.

A PVDF (Kynar) injector that uses a PVC flanged connection to reduce the cost. Used for dilute acid injection into reactor