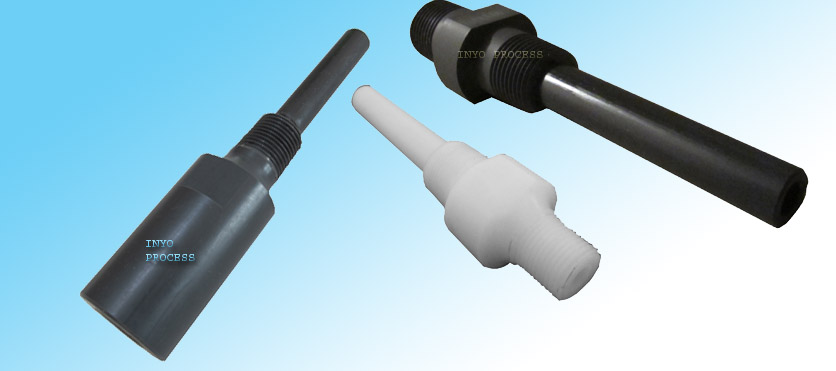

PVC, CPVC & Kynar Injection Quills Metal Injection Quills Multi-Orifice Injection Quills Teflon Injection Quills

PVC & CPVC & Kynar (PVDF) Injection Quills

PVC, CPVC & Kynar (PVDF) Injection Quills provide broad chemical compatibility for a variety of water and industrial chemical applications. These quills can be used with most acid & base solutions, and many chemicals including chlorine & ammonia.

PVC is an excellent all-around material up to approximately 130°F.

CPVC can provide many of the same properties as PVC up to approximately 180°F. Under some conditions, CPVC can become brittle as it ages, so PVC is recommended unless higher temperatures are present.

Kynar provides excellent chemical resistance properties up to approximately 225°F. Often used for strong/concentrated acids.

Maximum pressure: 150 psi

For suggestions on choosing a quill see the guide, Choosing an Injector or Chemical Diffuser System

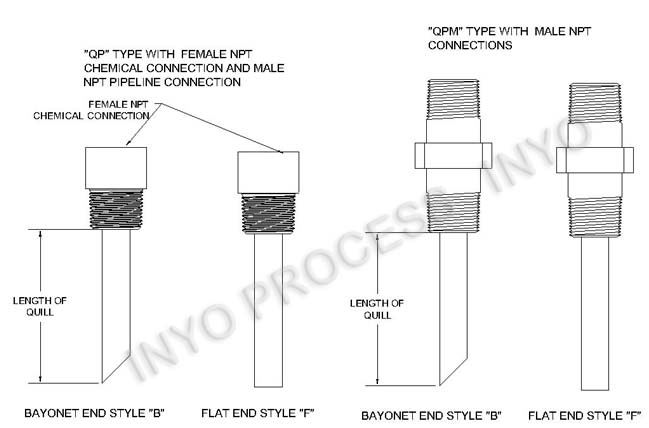

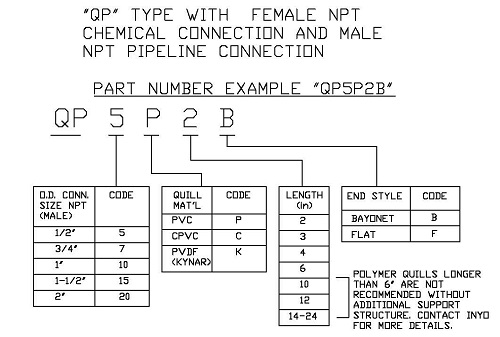

Plastics quill are offered in two configurations: QP & QPM

QP style - A male/female npt fitting with a female npt for the chemical connection that allows for easy connection to a pipe or threaded npt tube fitting.

![]() Download QP PVC & CPVC & PVDF (Kynar) Datasheet

Download QP PVC & CPVC & PVDF (Kynar) Datasheet

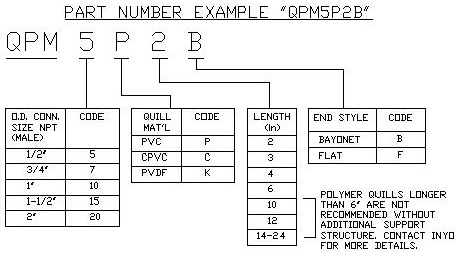

QPM style - A dual male npt end which allows for easy connection of a check valve or coupling or shut-off valve.

Download QPM PVC & CPVC & PVDF (Kynar) datasheet

Download QPM PVC & CPVC & PVDF (Kynar) datasheet

Custom Injection Quills

Inyo can provide a wide range of custom quills to meet your specific needs. Shown below are several examples

Several Kynar quills designed with a male end fitting for connection to a check valve

A PVDF (Kynar) quill designed with a removable steel support tube. This allows a longer injector to be used in a large pipeline without concerns for bending or breakage. Used in a meat processing plant's hot water process line for injecting a bromine solution.

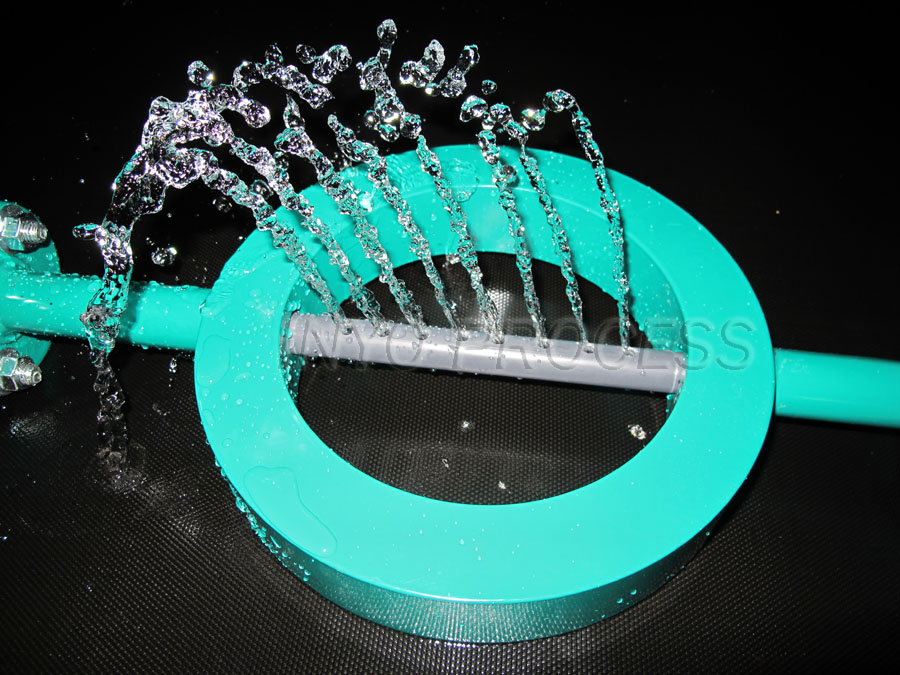

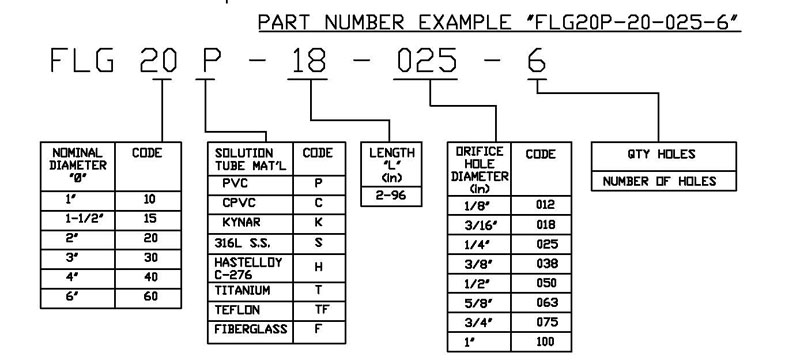

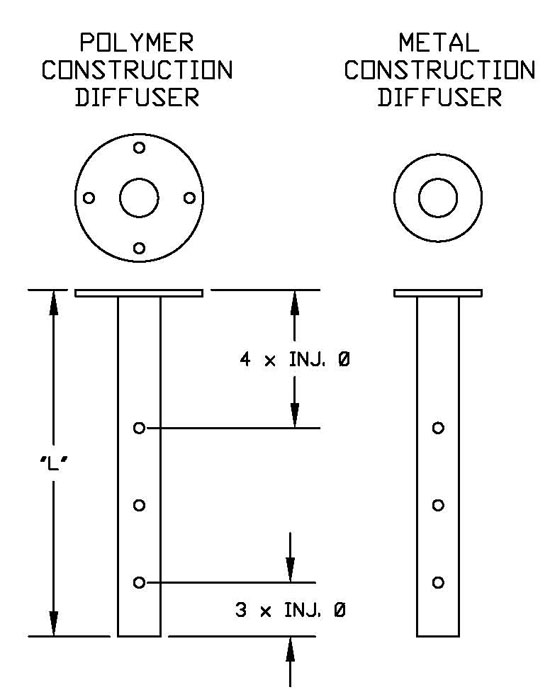

Flanged Chemical Diffusers

Multi-Orifice Design

Flanged diffusers are designed to fit into a flanged additive port. The diffuser flange is sandwiched between the flanged port and a mating blind flange or flanged pipe. They provide an easy method of distributing chemicals throughout the entire pipe diameter.

Sized for each application, they will include a multitude of orifice holes along the injector.

These smaller holes distribute chemicals throughout the pipe.Long service life with low maintenance-scaling liquids not issue due to thin wall/large diameter

As these chemical diffusers can be designed to be supported at both end of the pipe, PVC, Kynar and Teflon diffusers can have much longer solution tubes than the typical cantilevered unsupported diffuser.

Teflon diffusers are an excellent choice for concentrated sulfuric acid injection!

Chemical diffusersare available in a variety of materials including:

-

Teflon

-

Kynar

-

316L S.S.

-

Hastelloy C-276

-

Titanium

-

PVC

-

CPVC

-

Fiberglass

![]() Download Brochure for Flanged Diffusers

Download Brochure for Flanged Diffusers

![]() Download Typical Diffuser Installation Drawing (30 kb)

Download Typical Diffuser Installation Drawing (30 kb)

![]() Download specification for flanged diffuser

Download specification for flanged diffuser

Call us for a quote or to discuss your application.

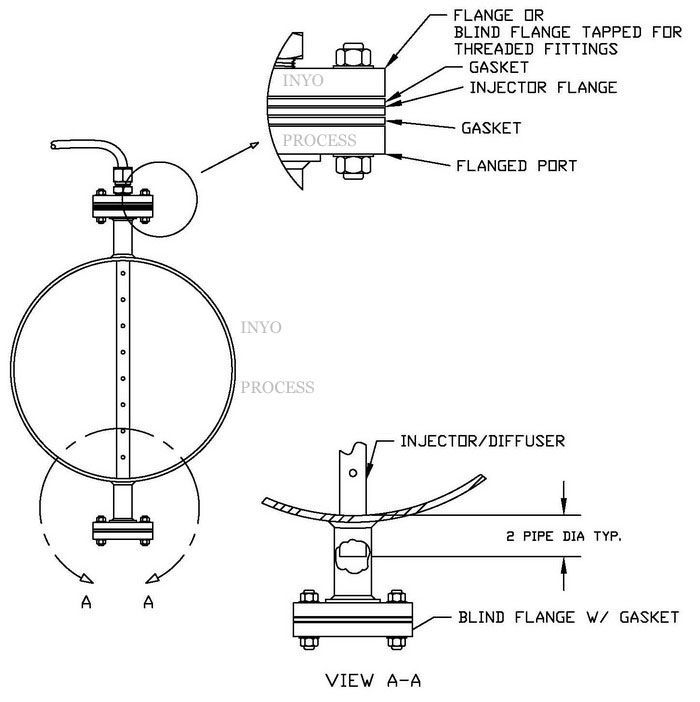

Typical Installation Detail

For longer length diffusers constructed from plastics, such as PVC, we can provide a metal support tube which allows for longer unsupported lengths. Ideal for larger pipelines and channel diffusers that require both a longer diffuser and the corrosion resistance of plastics. Great for Chlorine solutions, dilute acids, etc.

This PTFE lined Hastelloy tank diffuser was custom built to distribute concentrated sulfuric acid at higher temperatures across a tank diameter.

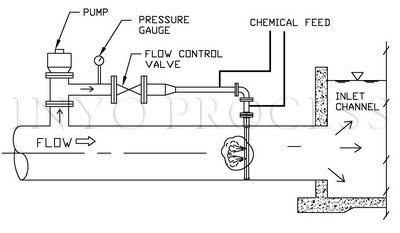

Jet Mixers

A jet mixer is created by using on or more nozzles or orifices to create a high velocity counter flow in a pipe or channel. This countflow jet creates considerable turbulence and mixing shear that results in a highly effective method of diffusing chemicals.

Jet mixers can be used for:

- Flash mixing of coagulants such as alum

- Disinfection including chlorination and chloramination

- Gas/liquid dispersion including aeration, CO2 addition for pH control and ozonation

One of the main advantages of a jet mixer is the simplicity of the design. The capital costs are low, and there are no moving parts except for the pump.

Typically a jet velocity of 20-30 ft/sec is used to properly disperse the chemicals.

Jet mixers use a high velocity injection flow submerged in a fluid to create turbulence and mixing shear which dissipates the energy.

Inyo Process can provide a range of solutions for tailored for your application. Give us a call!

Drawing of a Typical Jet Diffuser Layout

Details the General Arrangement of a typical multi-orifice injector set-up with carry water

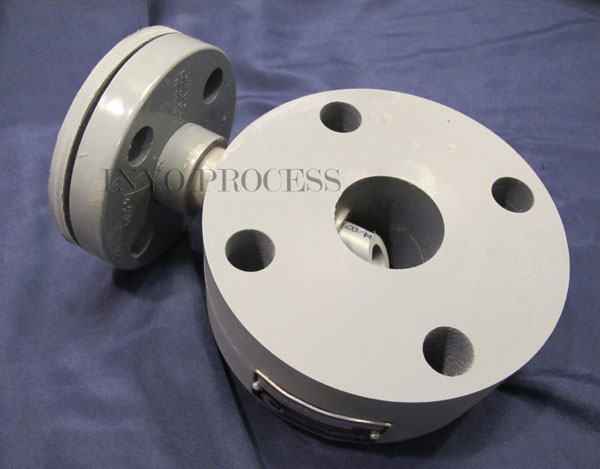

Mixing Tees

Mixing Tees are a simple, cost effective method of providing chemical diffusion to a system. Mixing tees typically have been offered in both a wafer style. We have now added to our product line a pipe spool configuration. There is little or no pressure drop across these devices, which rely on advanced chemical dispersion techniques.

Inyo mixing tees use custom designed injectors and now we have added to our product line are able to provide mixing tees with mixing wings to ensure through chemical dispersion.

Designed to fit between flanges, the Inyo Process mixing tee is usually designed with a flanged multi orifice injector injector/chemical diffuser that effectively distributes the chemicals throughout the pipeline.

Mixing Tees are available in a wide range of designs, including:

-

Stainless Steel

-

Teflon Lined Steel

-

FRP

-

PVC

-

Kynar

-

Epoxy Coated Carbon steel

Mixing Tees are a simple method of installing an injection point in an existing piping system.In many cases, the mixing tee can be installed with little or no piping modification!

Mixing Tees can be supplied in a pipe style and can include mixing elements that further enhance the mixing of the process flow

Inyo Process can offer injection solutions integrated with the Storm Mixer line of static mixers

We can supply a range of PTFE lined mixing tees for concentrated sulfuric acid.

Flanged PVC mixing tee provides excellent dispersion of sodium hypochlorite in water

Teflon Lined Mixing Tees, injectors, and spool pieces are also available

Shown is an example of a teflon lined injector constructed of all teflon lined components including a check valve. This particular injector was designed for adding sulfuric acid into a low pressure & temperature water/steam line.

Contact Inyo Process for more details

PTFE lined mixing tee with integral multi-hole injector designed to disperse large flow rates of sulfuric acid for greater diffusion.

Inyo Process can offer a wide range of mixing tees that are suited for your specific application. Contact us with your requirements

Sulfuric Acid injection mixing tee with hastelloy injector for refinery process

CPVC Mixing Tee with integral flanged injector